Thermal bridging is something that we, as an industry, have been hearing more and more about in recent years. With a drive towards more energy efficient homes, thermal bridging is becoming increasingly more important within the industry, as research shows it can account for up to 30% of all heat loss from buildings. The ever-increasing demand for energy efficient buildings, largely driven by changing legislation, has shifted the focus back onto architectural detailing and onsite construction practices. The first step should be minimising the heat loss through the fabric of the building in a bid to reduce thermal bridging. But what actually is thermal bridging?

What is Thermal Bridging?

In terms of a building, a thermal bridge is part of the building envelope through which heat is transferred at a substantially higher rate than through the surrounding area. The heat losses at these junctions are considered independently of the u-values of the elements. For example a thermal bridge is created when a lintel spans between the inner and outer leaf of a cavity wall, allowing heat to flow through the path created by the lintel from inside the building to the outside environment.

It has become apparent that significant heat is lost through thermal bridging, therefore building regulations now require the heat loss through U-Values and Thermal Bridging (Psi values) to be accounted via SAP calculations. Compliance with SAP calculations is a requirement for all new build to pass building regulations.

Types of Thermal Bridging

There are two main types of thermal bridges in buildings; repeating and non-repeating. Repeating thermal bridges occur regularly within a typical dwelling; for example, where timber studs bridge a layer of insulation in a cavity wall. These are taken into account in the ‘U-value’ calculation (a measurement in m2 of the effectiveness of a material as an insulator).

Non-repeating thermal bridges occur at junctions between building elements and around openings, these are measured as Psi values (linear thermal heat transmittance). The Psi values are accounted for in the SAP calculation.

Thermal Bridging and Psi Values

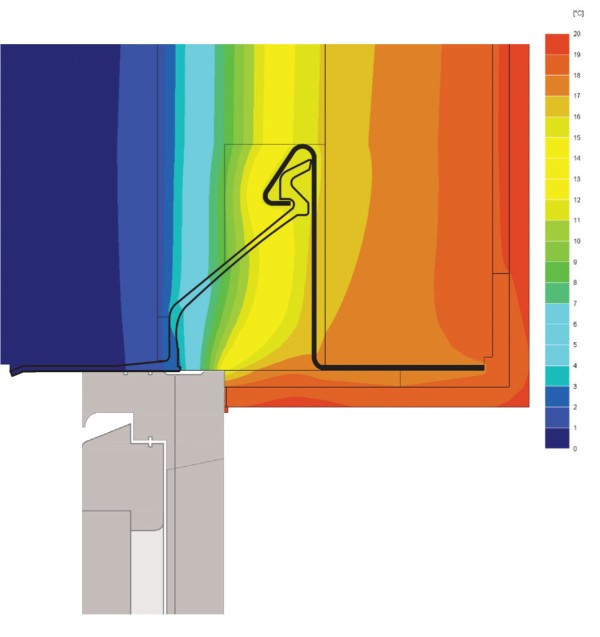

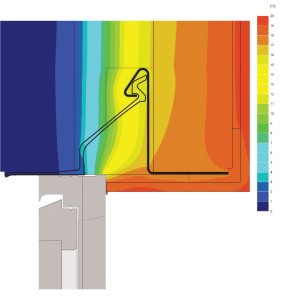

Another term we often hear is ‘Psi Values’. Non-repeat thermal bridging is measured as a Psi Value, which is a measure of linear thermal heat transmittance usually at a junction in a dwelling. A Psi value is calculated using specialist thermal modelling software, where the thermal modeller will draw the construction detail in the software package and add in the material conductivities. This sophisticated software then calculates the heat loss at the junction, subsequently producing a Psi value.

Psi values are based on standard construction details but default Psi values can be enhanced through the use of thermal modelling by a third party-accredited assessor. Improved Psi values can help eliminate the need for costly eco add-ons, such as solar panels, and are worth exploring as a means to reduce the cost of a new build whilst meeting fabric requirements, energy requirements of Part L of the building regulations and Code of sustainable homes.