Extended

Range

Stainless Steel Coastal Solutions

Hi-therm+ is also available with a stainless steel outer leaf & galvanised steel inner leaf for use in coastal regions and severely exposed areas.

The use of stainless steel is ideal when the life expectancy and maintenance programme of a building are key design considerations, for example, in specialist laboratory or medical applications, hospitals, residential care homes, schools, prisons and institutional buildings.

Stainless steel is suitable in these developments because of its outstanding anti-corrosion properties.

British standard publication PD 6697 Recommendations for the design of masonry structures’ recommends the use of stainless steel lintels in buildings that are subjected to aggressive environmental conditions and buildings exceeding three storeys.

There is also a requirement for NHBC registered projects to use stainless steel lintels in coastal locations, namely within 500m of the shoreline.

Product information

-

All stainless steel lintels are manufactured from austenitic stainless steel, grade 304 2b to BS EN 10088- Part 2 Astm 240 (European Grade 1.4307).

-

All stainless steel lintels are made to order, specific to each application.

- Other grades of stainless steel are available upon request.

Loading Guide Tables

Cavity Wall Wide Inner Leaf

125 – 150mm

| Cavity Widths (mm) | Standard | Heavy Duty | Extra Heavy Duty |

|---|---|---|---|

| 90-105 | HT/S+ 100 WIL | HT/HD+ 100 WIL | HT/XHD+ 100 WIL |

| 110-125 | HT/S+ 110 WIL | HT/HD+ 110 WIL | HT/XHD+ 110 WIL |

| 130-145 | HT/S+ 130 WIL | HT/HD+ 130 WIL | HT/XHD+ 130 WIL |

| 150-165 | HT/S+ 150 WIL | HT/HD+ 150 WIL | HT/XHD+ 150 WIL |

Cavity Wall Wide Outer Leaf

125 – 150mm

| Cavity Widths (mm) | Standard | Heavy Duty | Extra Heavy Duty |

|---|---|---|---|

| 90-105 | HT/S+ 100 WOL | HT/HD+ 100 WOL | HT/XHD+ 100 WOL |

| 110-125 | HT/S+ 110 WOL | HT/HD+ 110 WOL | HT/XHD+ 110 WOL |

| 130-145 | HT/S+ 130 WOL | HT/HD+ 130 WOL | HT/XHD+ 130 WOL |

| 150-165 | HT/S+ 150 WOL | HT/HD+ 150 WOL | HT/XHD+ 150 WOL |

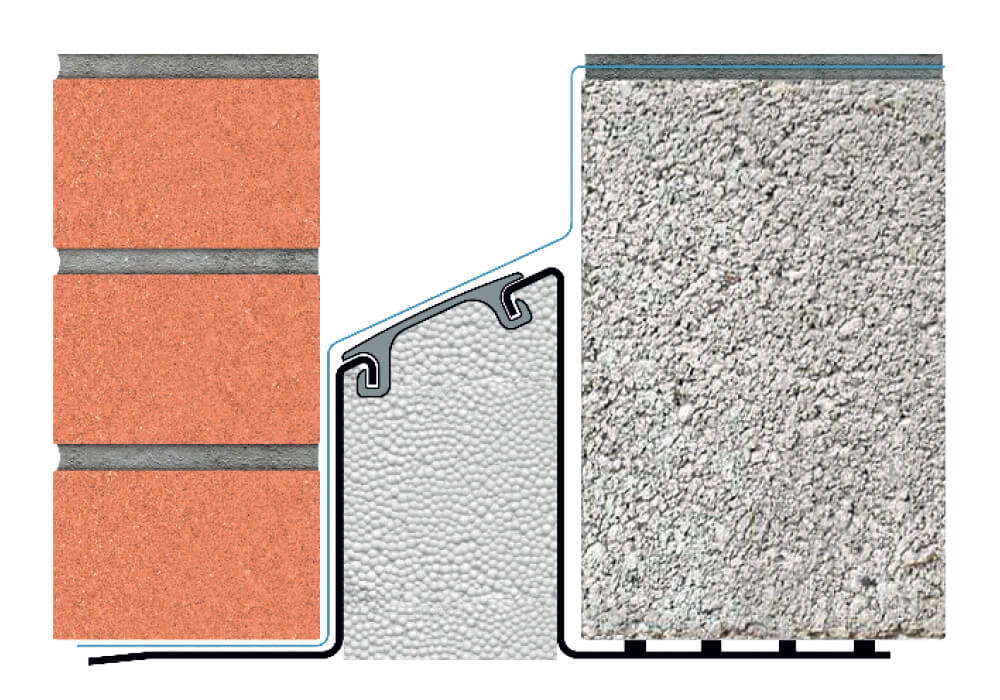

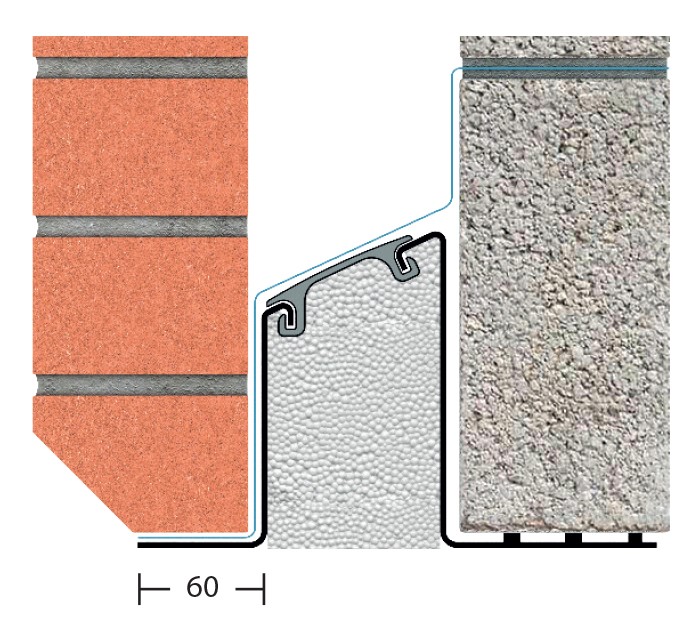

Cant Brick Lintel

The Cant Brick Lintel can be supplied to suit all lintel profiles for 100-165mm wide cavities.

Example specification: HT/S+100 (CB 60mm).

Stop Ends

A Stop End is required at each end of a lintel to prevent moisture cascading over the ends into the cavity and onto the inside wall.

The use of stop ends quickly and economically removes the risk of water being directed into the cavity.

Stop Ends can be fixed to the outer leaf of the lintel using a butyl anchoring strip, ensuring the Stop End is secure at the end of the lintel in the most appropriate position to suit the masonry perp joint.

When fitted, moisture from the lintel is directed outwards through brickwork weeps.

Standard Stop End