NCCTL

Non-combustible

Cavity Tray Lintel

The Compliant Solution

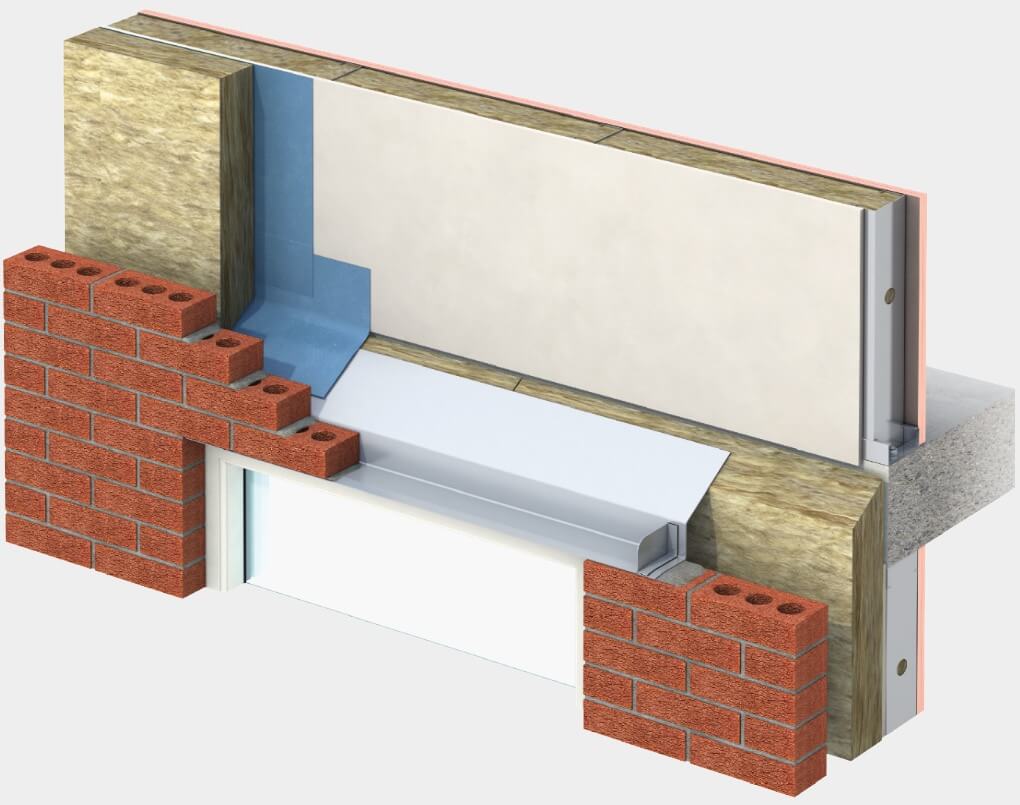

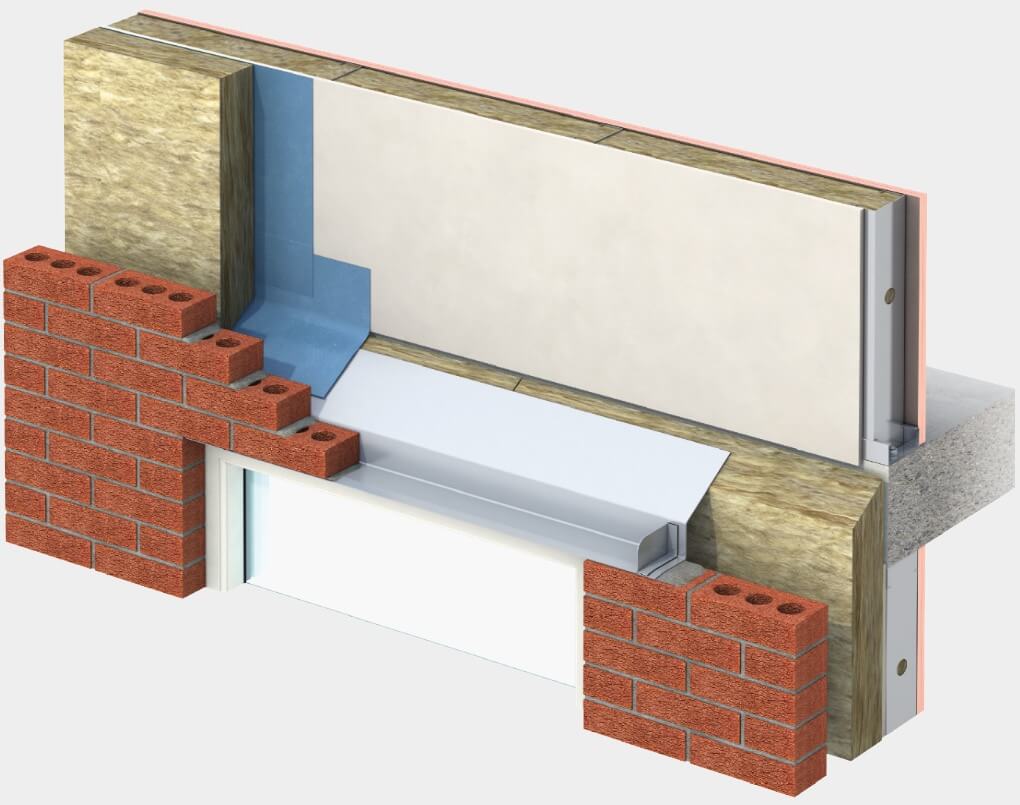

The Keystone Non-combustible Cavity Tray Lintel offers a non-combustible stainless steel single leaf lintel with combined cavity tray.

For use in an exterior masonry skin in conjunction with a non masonry inner leaf such as a steel frame system, the NCCTL is a highly efficient and practical solution to the challenge of non-combustible cavity detailing. Manufactured in Class A1 grade 304 austenitic stainless steel, the NCCTL represents the ideal specification for all applications requiring Document B compliance. The NCCTL can also be ordered in grade 316 austenitic stainless steel if required in coastal locations.

Benefits

Fit and forget

The NCCTL is a practical lintel solution which is built into the outer leaf as normal and gives easy access to membranes and insulation on the inner leaf. The ease of installation in the outer leaf combines the structural load bearing lintel with the advantages of a self supporting cavity tray.

Part B compliant

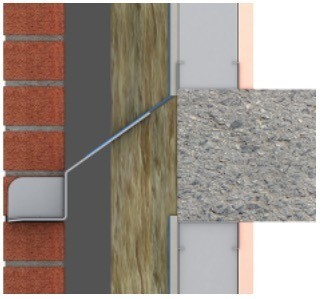

Materials which become part of an external wall, or specified attachment, of a relevant building are of European Classification A2-s1, d0 or A1, CLASSIFIED IN ACCORDANCE WITH BS EN 13501-1:2007+A1:2009

Cavity Tray requirements

NHBC Standards clause 6.1.12 Lintels states that cavity trays should be provided at all interruptions to the cavity (e.g. windows and door openings and air bricks) Unless Otherwise Protected.

- Non-combustible Class A1 for compliance with Document B in buildings over 18m high

- Stainless steel construction with mechanically fixed watertight stop ends

- Facilitates speedy installation

- Utilises traditional onsite trades, no special skills required

- Standard load-bearing capabilities

Ease of Installation – Fit and forget

The NCCTL is a practical lintel solution which is built into the outer leaf as normal and gives easy access to membranes and insulation on the inner leaf.

The ease of installation in the outer leaf combines the structural load bearing lintel with the advantages of a self supporting cavity tray. These features allow the profiling of insulation

and the overlap positioning of the cavity facing membrane, if required. This should be completed independently, once the lintel is securely built into the brickwork.

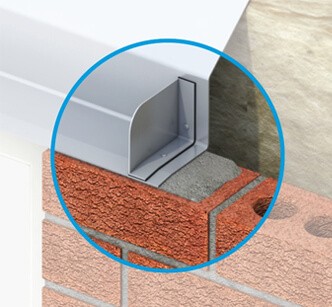

Patented Mechanically Fixed Stopends

Watertight mechanically fixed sealed stop-ends are positioned within brickwork perpendicular joints. The patented mechanically fixed stop-ends remove additional operations usually performed by the bricklayer and ensure any moisture present on the NCCTL cannot travel horizontally over the ends of the lintel but is channelled outwards instead.

The NHBC states that the single biggest reason for buildings already occupied to be reopened is problems relating to stop-ends, joints in cavity trays and DPCs around lintels. IG’s patented mechanically fixed solution alleviates installation errors onsite.

Loading Assessment

The NCCTL accommodates openings up to 2822.5mm as standard. Contact the Keystone Lintels technical team for openings over 2822.5mm.

Adjustability

Mechanically fixed stopends are prepositioned within the perpend joint to accommodate brickwork openings.

Standard Range

– Lintel lengths are based on brickwork openings sizes

– Lintel range is based on 215mm stretcher bond as standard

– NCCTLs accommodate openings up to 2822.5mm as standard

Other variations are available on request. Please contact the

Keystone Technical engineers with requirements for any variation from the above.