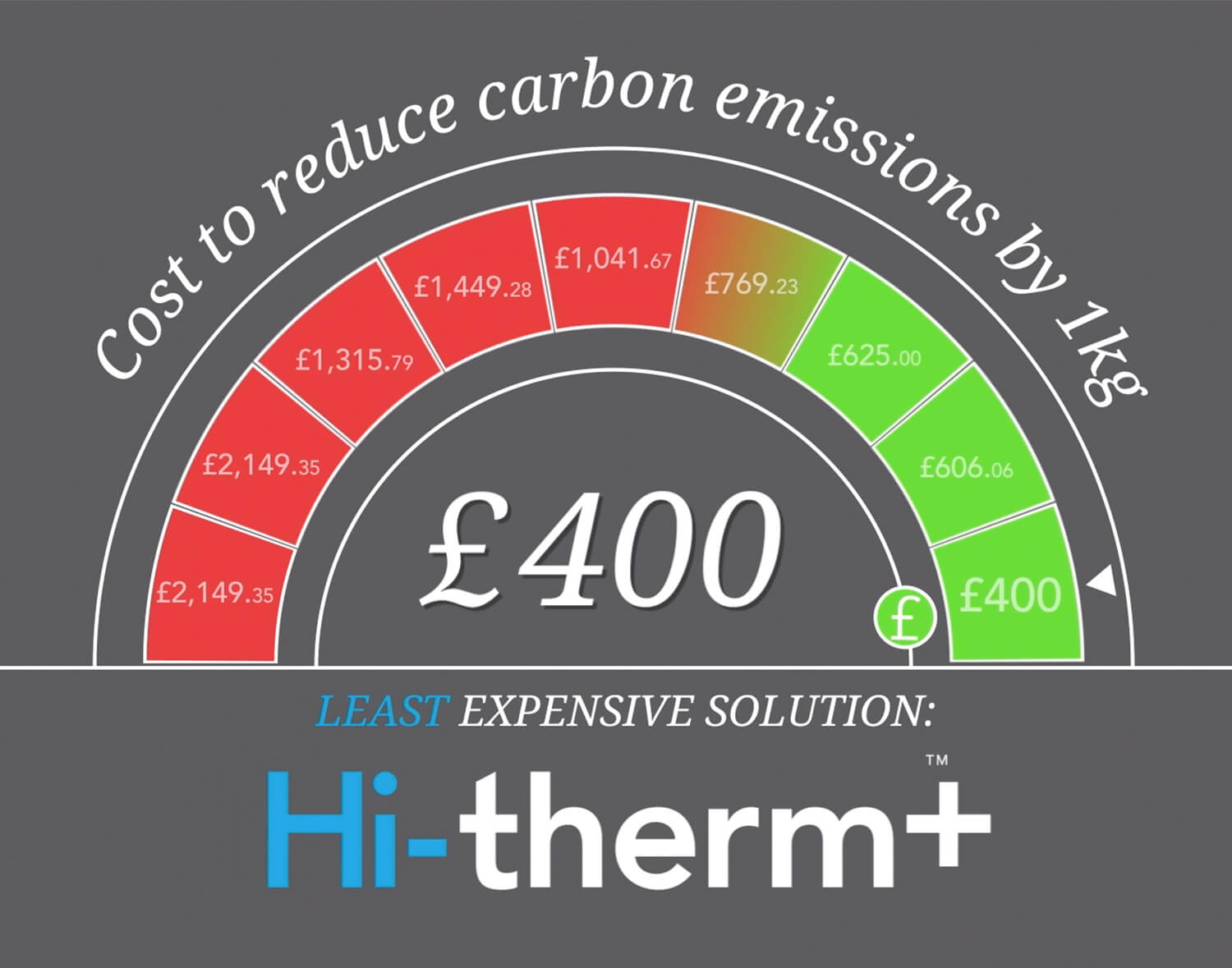

#1 low cost solution to reduce carbon emissions

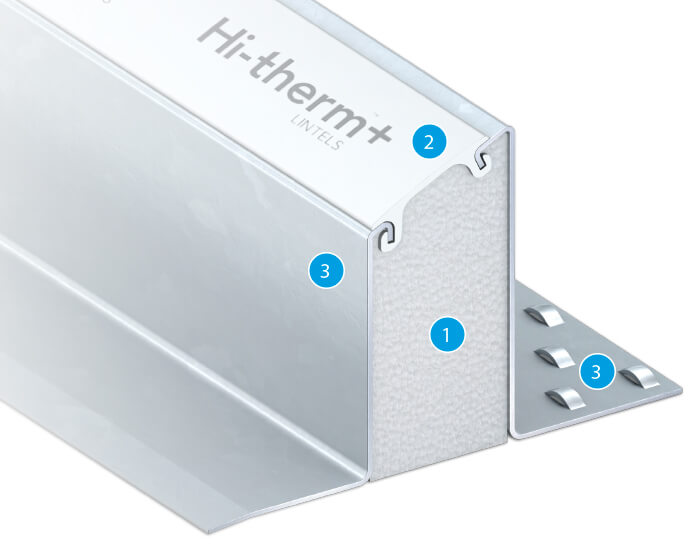

The genius is in our patented polymer isolator.

Up to 5 times more Thermally Efficient than a Standard steel Lintel

Thermal Efficiency

Psi Value: 0.03-0.06

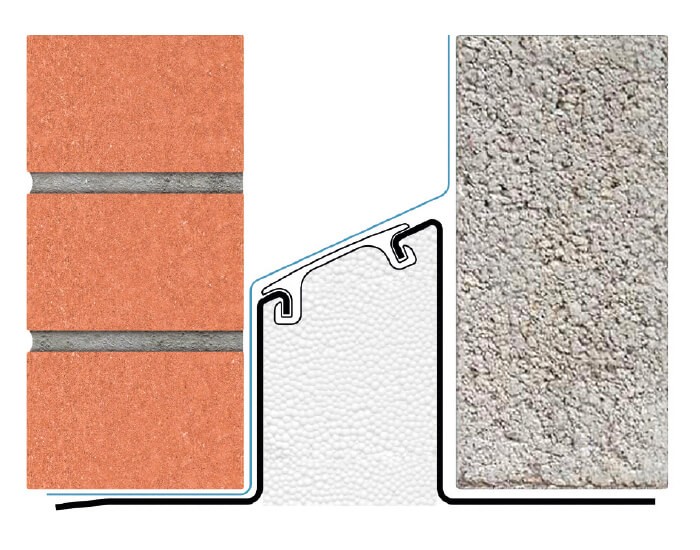

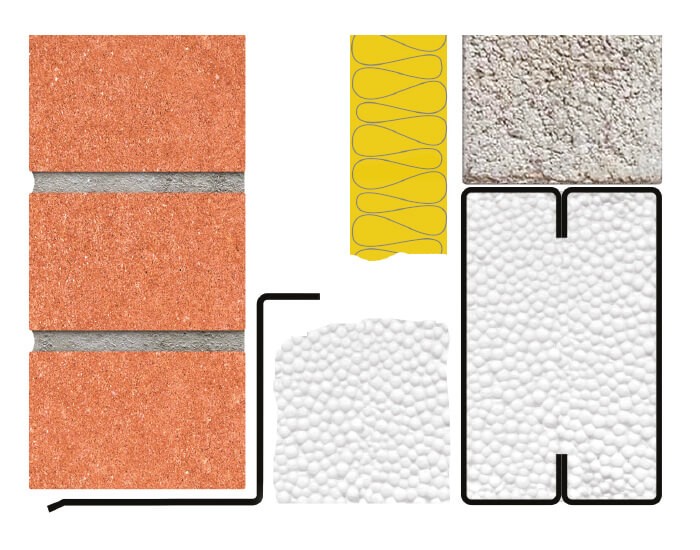

Insulation: Prefitted expanded polystyrene insulation enhances the thermal performance of the lintel.

Insulation: Prefitted expanded polystyrene insulation enhances the thermal performance of the lintel.

Polymer Thermal Isolator: Rigid polymer thermal isolator acts as an effective thermal break.

Polymer Thermal Isolator: Rigid polymer thermal isolator acts as an effective thermal break.

Galvanised Steel: Galvanised steel inner & outer leaf.

Galvanised Steel: Galvanised steel inner & outer leaf.

Cost Effective

Hi-therm+ offers a cost effective solution to lowering carbon emissions within SAP, offering significant savings compared to other popular alternatives.

For example in a comparative case study for a house type, using Hi-therm would incur less than 20% of the cost of increasing the cavity width by 50mm for the same saving in Co².

These Co² savings are important within SAP because they give flexibility for compliance in situations where other built details are not meeting the standards in Appendix R.

Cost Effective

Hi-therm+ offers a cost effective solution to lowering carbon emissions within SAP, offering significant savings compared to other popular alternatives.

For example in a comparative case study for a house type, using Hi-therm would incur less than 20% of the cost of increasing the cavity width by 50mm for the same saving in Co².

These Co² savings are important within SAP because they give flexibility for compliance in situations where other built details are not meeting the standards in Appendix R.

Gospel Oaks | Wrekin Homes

Hi-therm saved more than £200 per plot by enabling the use of a reduced cavity width.

Buildability

Hi-therm+ offers the simplicity of a one piece, structurally superior top hat design creating stability during the building process, unlike a two part lintel solution. Hi-therm+ is manufactured with a wider range & longer lengths.

BBA Approved

Good Detailing – Hi-therm+

- Hi-therm+ closes the cavity.

- The single component design simplifies installation.

- The one piece design assists stability between the internal & external leaves and creates stability during the build process.

- Hi-therm+ gives cost certainty with no additional costs.

Poor Site Detailing – Split Lintels

- A cavity closer must be supplied and fitted ££.

- Requires two separate lintels with double handling & installation labour ££.

- Individual lintels will require propping & additional wall ties will be required to overcome the lack of inherent stability in a split lintel solution ££.

- ££ = Additional Costs.