The pressure is on for the construction industry to deliver and meet the Prime Minister’s challenge to ‘build, build, build’ the country out of recession. In order to achieve the government’s 300,000 new homes per year pledge to tackle the long-standing property shortage, time and cost-efficiency will be key to satisfying this demand, but build quality must not be sacrificed in the process.

The pressure is on for the construction industry to deliver and meet the Prime Minister’s challenge to ‘build, build, build’ the country out of recession. In order to achieve the government’s 300,000 new homes per year pledge to tackle the long-standing property shortage, time and cost-efficiency will be key to satisfying this demand, but build quality must not be sacrificed in the process.

The need for construction standards to be maintained throughout building projects large or small was outlined in Dame Judith Hackitt’s review of building regulations and fire safety. In the report, which followed in the wake of the 2017 Grenfell Tower tragedy, she called for the sharing of a ‘golden thread’ of information to ensure best practice was upheld between all stakeholder links in the building supply chain. This requirement for increased transparency can be linked to a part of the review in which Dame Hackitt said there was a tendency within the construction industry to go off-plan and base product and material selection on cost rather than suitability.

Testing and Quality

While cost is undoubtedly a huge factor, it’s more important than ever that savings do not come at the expense of quality or performance, particularly where critical structural components such as a lintel, for example, are concerned. Manufacturers of such building products have a big responsibility and should have testing and quality at the top of their agenda. Indeed, the findings of the Hackitt report stated precisely that. It said manufacturers of construction products used in buildings where performance standards apply ‘should ensure that testing is verified by an independent third party certification body’. At Keystone, we take this responsibility very seriously.

All of Keystone’s lintel products are third party-accredited by the British Board of Agrément (BBA). Transparency is key, and we work closely with the BBA and invest in rigorous testing so that we can offer quality assurances. Claire Curtis-Thomas, CEO of the BBA has spoken previously of her passion for this cause. She said third party certification was “absolutely vital” because if it wasn’t there “then people would be left to effectively declare their own performances”.

In October 2018, the BBA in conjunction with Local Authority Building Control (LABC), launched 100% Hackitt, a joint venture to urge the government to introduce all 53 of Dame Hackitt’s recommendations. Claire Curtis-Thomas, BBA Chief Executive, described the 100% Hackitt initiative as “the best thing for the British construction industry in a generation”, adding: “The BBA is backing this initiative as strongly as we possibly can because we want to see bad practices in the industry eliminated and protection for the public and companies that are fully committed to high standards of delivery.” Paul Everall, LABC Chief Executive added: “The LABC and the BBA share the same outlook and are determined to make a difference in our industry. “But we’re not waiting, we’re getting on with building a safer future together – right now.”

Unfortunately, the building process is still being hampered by manufacturers offering cheaper products which may not carry third-party accreditation. Therefore, the construction industry must demand quality and testing to reduce the performance gap and maintain standards.

Thermal Efficiency

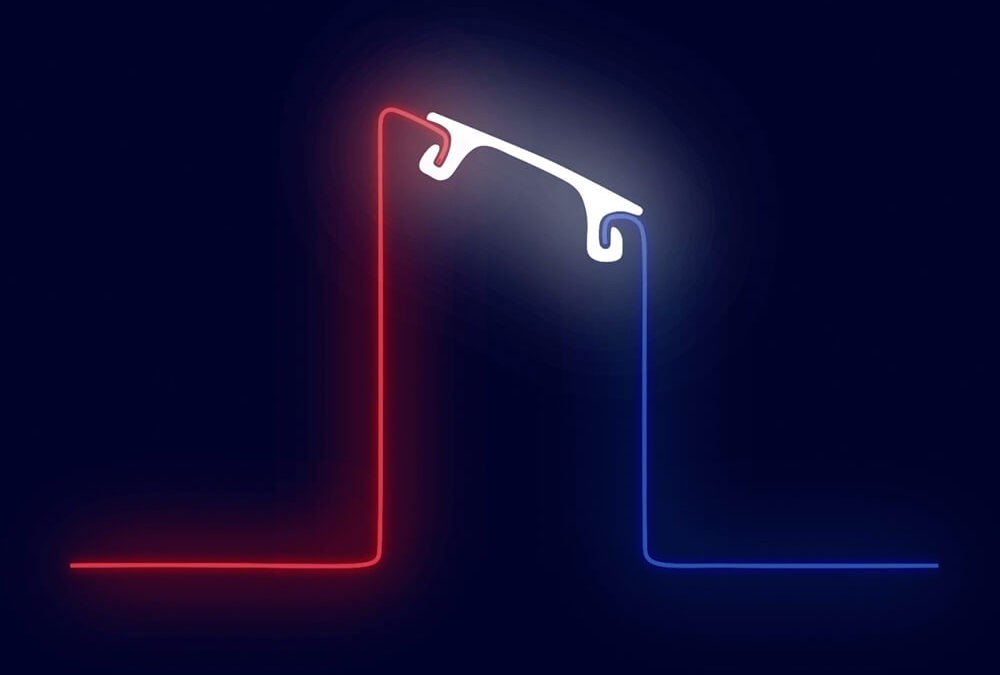

A bigger focus in recent years on the thermal efficiency of products and materials that make up a building’s fabric, has led to opportunities to develop and innovate new solutions. With lintels, for example, there is now a range of thermally-advanced steel lintels available on the market that eliminate this key thermal bridge in buildings. However, it’s essential that the lintel continues to offer structural support, which is its primary function. This is why obtaining third party accreditation on this new type of lintel is extremely important.

Keystone has set new standards for thermal efficiency in steel lintels. Its award winning Hi-therm Lintel has a significant impact on the thermal efficiency of homes and is specified on many projects around the UK due to its improved performance in lowering carbon emissions within SAP.

When we re-engineered Hi-therm+ lintels with our industry leading top hat design, we recognised the importance of third party testing and certification for this new type of product. Keystone’s Hi-therm+ lintel has trusted third party certification from the BBA, which has tested the design, strength, performance, durability and fire resistance to ensure the product is fit for purpose. Encouraging the safe development and adoption of innovative solutions in construction manufacturing is crucial.

Responsible builders will always insist on products that have been tested and verified by a third party. We need them to rise to the challenge of building homes as intended, while ensuring quality and standards are maintained.

Recent Comments